Case Histories

Chicago Aluminum Castings Company, Inc. is an aluminum sand casting specialist, providing molding inserts and serving industries across the nation since 1910. We work with many aluminum alloys. We are fully equipped to provide engineering services, prototypes, and production runs up to 120 lbs. net casting weight.

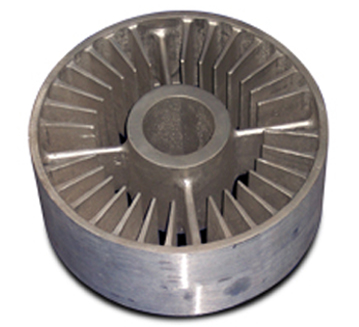

Heat Sink Conveyor Pulley

| Customer: | Major Food Processing Company | |

| Alloy: | ALMAG 35 | |

| Weight: | 18 lbs. | |

| Dimensions: | 12 1/2″ dia. 5″ thick | |

| Comments: | Cast with complex core assembly. Original part was more expensive welded fabrication. |

Four-wing Beater

| Customer: | Food Processing Equipment Manufacturer | |

| Alloy: | ALMAG 35 | |

| Weight: | 2 lbs. | |

| Dimensions: | 13″ high 8 1/2″ wide | |

| Comments: | Replaces welded steel wire fabrication; lighter and less expensive and more efficient than original part. Only machining required is boring of shaft hole. |

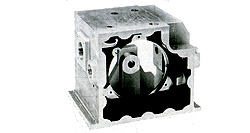

Machinery Gear Housing

| Customer: | Coil Winding Equipment Manufacturer | |

| Alloy: | ALMAG 35 | |

| Weight: | 26 lbs. | |

| Dimensions: | 9″ high 11″ wide 8″ deep | |

| Comments: | Cast with 5 cores. Replaces cast iron part weighing 72 lbs. Reduced machining costs. |

Multiple Drill Head Base

| Customer: | Major Machine Tool Manufacturer | |

| Alloy: | ALMAG 35 | |

| Weight: | 20 lbs. | |

| Dimensions: | 19″ dia. 7 1/2″ high | |

| Comments: | Casting includes 29 cored holes requiring only reaming reducing customers machining costs. |

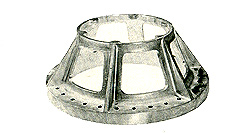

Sieve Shaker for Soil Tester

| Customer: | Well known Scientific Instrument Manufacturer | |

| Alloy: | ALMAG 35 | |

| Weight: | 5 1/2 lbs. | |

| Dimensions: | 13″ dia. 1 1/2″ thick at hub | |

| Comments: | Replaces a 15 lb cast iron part. Casting includes steel center insert. Lighter aluminum part allowed a reduction in size of drive motor. Reduced machining costs by 80%. |

2647 West Ogden Ave., Chicago, IL 60608

Ph: 800-571-0242 | Fax: 773-762-3011 | sales@chicagoaluminum.com

© Chicago Aluminum Casting Co., Inc. | All rights reserved. | Design-2-Part Web Design